Our expertise in innovative industrial cleaning

Innovative technologies and the functioning of industrial cleaning

Discover the latest technologies for cleaning machines, industrial plants, vehicles, buildings, etc. This is the functionality of surface treatments using lasers, plasma and dry ice:

- Exemplification of the principle of laser cleaning

- Explanations of the effect of plasma cleaning

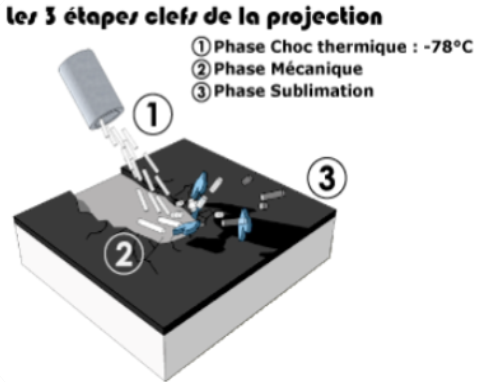

- Illustration of the function of dry ice blasting

Use cases of innovative cleaning

For which applications are innovative industrial cleaning processes suitable?

Discover the advantages for

- the elimination of soiling

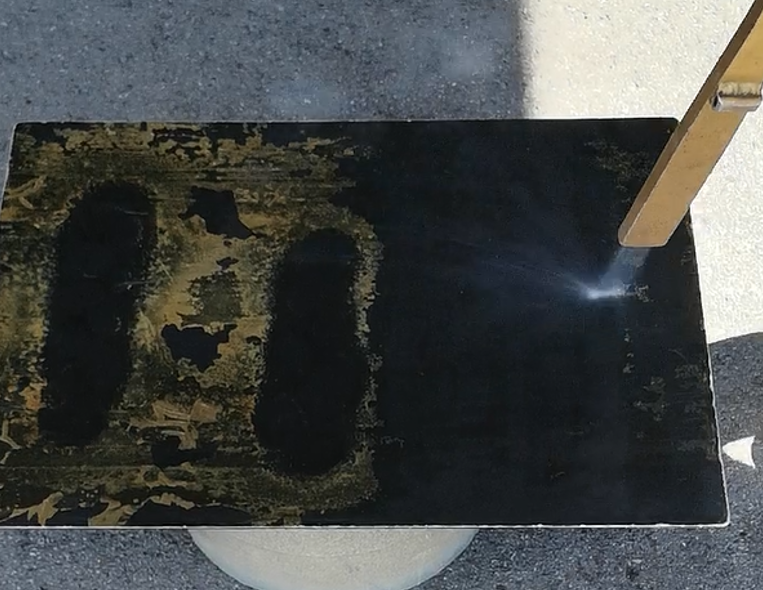

- the removal of incrustations

- derusting

- the homogenisation of surfaces

- the stripping or degreasing of materials

- the removing of graffiti, excrement, etc.

- the decontamination after fires and other accidents

- the disinfection against viruses, bacteria, etc.

- the maintenance of machines and equipment

- the detachment of wallpaper, paint and varnish

- the cleaning of moss and other coatings

Innovative cleaning by industry

Which industries can benefit from innovative cleaning processes?

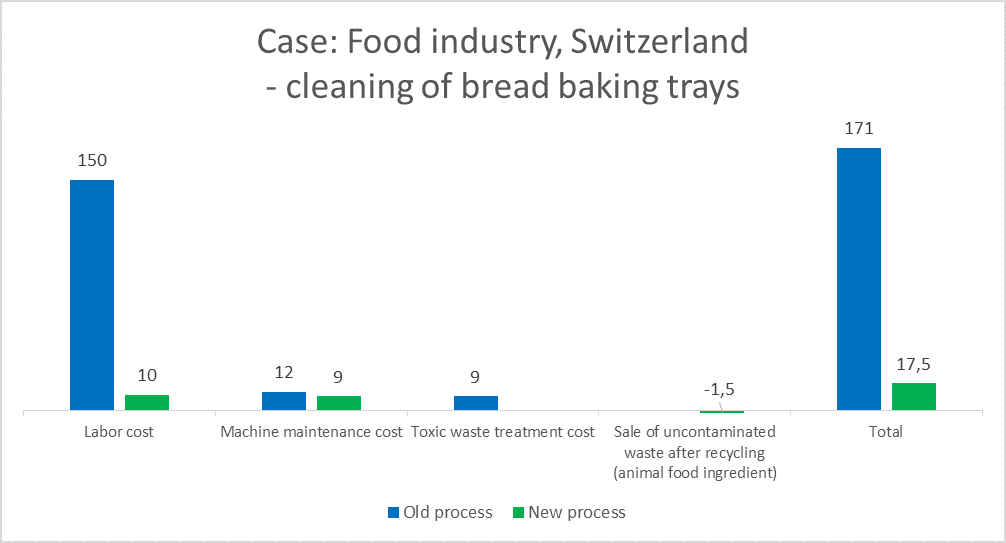

- Food industry

- Agricultural sector

- Catering service provider, gastronomy, events and tourism

- Automotive industry

- Workshops for vehicles, maintenance and repair

- Aircraft construction, shipbuilding, aeronautics and space

- Travel and transport and logistics

- Chemical / pharmaceutical industry

- Utilities for electricity, water, gas as well as waste disposal and recycling companies

- Public administration, municipal cleaning and maintenance companies

- Historic preservation, restoration

- Construction, building / civil engineering / road construction

- Mechanical and plant engineering

- Discrete and process manufacturing

- Consumer goods production

- Other manufacturing industry

Materials and surfaces to be cleaned

Sensitive surfaces, in particular, benefit from these gentle, non-abrasive processes. Even hard-to-reach areas or those that would only be accessible for manual cleaning after disassembly can be cleaned quickly and easily with our non-contact methods. What materials can be cleaned with innovative processes?

- Metal materials can be easily cleaned: e.g. iron, copper, bronze and metal alloys, such as stainless steel

- Mineral or inorganic materials benefit from gentle cleaning processes without abrasion: rock, ceramic, glass

- Plastic materials can be cleaned even if they are cables or other insulation of live parts

- Composite materials are suitable for treatment with innovative cleaning methods, e.g. carbon, concrete, etc.

- Hard organic materials such as wood

Profitability of cleaning processes

Innovative cleaning methods allow you to improve in many ways: money, quality, time and overall profitability.

Think about how much it currently costs to clean your engines, equipment, generators, manufacturing facilities, sites and vehicles.

In your calculation, do include:

- Production loss due to downtime

- Labor cost of dismantling and re-assembly

- Transport of pieces to be cleaned to cleaning facility and back

- Actual cleaning

- Waste disposal

- Depolluting of harmful substances

- Cost of quality loss due to residues and abrasion after cleaning

Innovative cleaning solutions also aid in the early detection of defects and the elimination of fire hazards:

- Faults in the hydraulic system

- Defects in the electrical system

- Leaks and cracks

Traditional cleaning by hand can make the working environment stressful and harmful. The new cleaning processes also have many advantages in terms of ergonomics and safety at work:

- No contact with caustic and harmful cleaning agents

- No physical strain during disassembly and assembly of the parts to be cleaned

- Better ergonomics when cleaning hard-to-reach areas

- No accidents during disassembly and reassembly of the machines to be cleaned

All of this results in more satisfied teams and less sick leave.

Industrial cleaning and the environment

How can you reliably remove soiling? With aggressive or abrasive chemicals that harm the material being cleaned and the environment? With a lot of time and manpower, while the cleaners must be protected from aggressive cleaning products?

No, today it is possible to do it better, faster and more ecologically: with innovative, cost-effective and people-, material- and environment-friendly cleaning methods such as cryogenics, laser and plasma.

Modern cleaning and surface treatment processes using laser, dry ice and plasma technology help to improve the environmental balance of operational processes:

- No water is consumed.

- There is no residue or contamination that would have to be disposed of at great expense.

- No harmful or toxic cleaning agents are used.

Other benefits for environmental protection:

The quality of the parts to be processed remains consistently high. This reduces scrap and therefore avoids waste.

The recycling of building materials is often only possible after removing surface coatings and contamination.

After a disaster such as a fire, much damage and contamination is often left behind.

When disinfecting against viruses, bacteria, etc., the quick and non-contact application of an ethanol-based disinfectant by gasification of dry ice is much more environmentally friendly than the use of H2O2-based disinfectants, which can be harmful to humans and nature.

Machines and equipment for cleaning in industrial applications.

For every situation, every surface and every type of dirt, there are suitable innovative processes, machines and accessories.

We will be happy to advise you on the most cost-effective machine for you and provide you with a tailor-made offer.

Situations where different machines are used:

- Application in a difficult to access area

- Very sensitive application

- Application requiring high aggressiveness

- Application under voltage

Workplace with a high explosive atmosphere (ATEX)

Accessories that can be used in the treatment:

- Personal protective equipment (PPE; hearing and respiratory protection, gloves, helmet, goggles, dust masks, safety shoes, etc.)

- Hose / extension

- Nozzle

- Cleaning materials such as dry ice

- Abrasive

- Other

A tailor-made offer for an innovative process cleaning machine is available for:

- Purchase

- Rental

- Leasing

- Additional options (maintenance, support, warranty, …)

Training, studies and industrial cleaning services

Studies:

Since each project is special, we customize all of our services and goods. Our efforts are focused on identifying your needs in order to provide you with the best possible solution. This analysis saves time and resources while ensuring long-term profitability.

The analysis will show you the savings compared to your current costs and profitability.

Training:

The handling of laser, plasma and dry ice cleaning processes must be learned. That is why we offer you and your team the appropriate training and familiarisation:

- How to adjust the machines?

- How to operate the machines safely and securely?

- What is the most effective cleaning method for this type of product?

- What are the mistakes to avoid?

- Etc.

Cleaning services:

If you prefer to outsource the cleaning work or if you only need to clean a specific object, we can take care of the cleaning for you with our team.

Situations in which you might prefer to outsource cleaning are, for example:

- Initial cleaning of an object before its first use

- Cleaning for maintenance, which occurs only once over a long period of time

- Post-disaster cleaning and decontamination

- Cleaning prior to reconstruction or dismantling on a production site

- Etc.

Where are our products and services available?

Our studies on the cost-effectiveness of innovative industrial cleaning and surface treatment processes are available worldwide.

We also supply the machines adapted to the respective needs as well as the corresponding accessories throughout the world.

Ideally located in the Greater Region of Luxembourg, the French Grand Est area – comprising the regions of Lorraine, Alsace and Champagne-Ardenne with the departments of Moselle, Meurthe-et-Moselle, Meuse, Ardennes, Aube, Marne, Haute-Marne, Bas-Rhin, Haut-Rhin and Vosges – the Belgian Walloon region and the German states of Rhineland-Palatinate and Saarland, we offer our services from the heart of Europe. We also serve many happy customers in countries bordering the Grand Duchy of Luxembourg, such as Belgium, Germany and France, with innovative technologies such as cryogenics, laser and plasma.

We also cover other countries such as Switzerland, Austria, the Netherlands, Spain, Portugal, Italy and the rest of Europe, North Africa, the Middle East, etc., either directly or through our network of international partners.

We deliver dry ice not only directly, but also by courier or by mail, depending on the customer’s requirements, the quantity and the destination. Contact us and we will be happy to advise you.